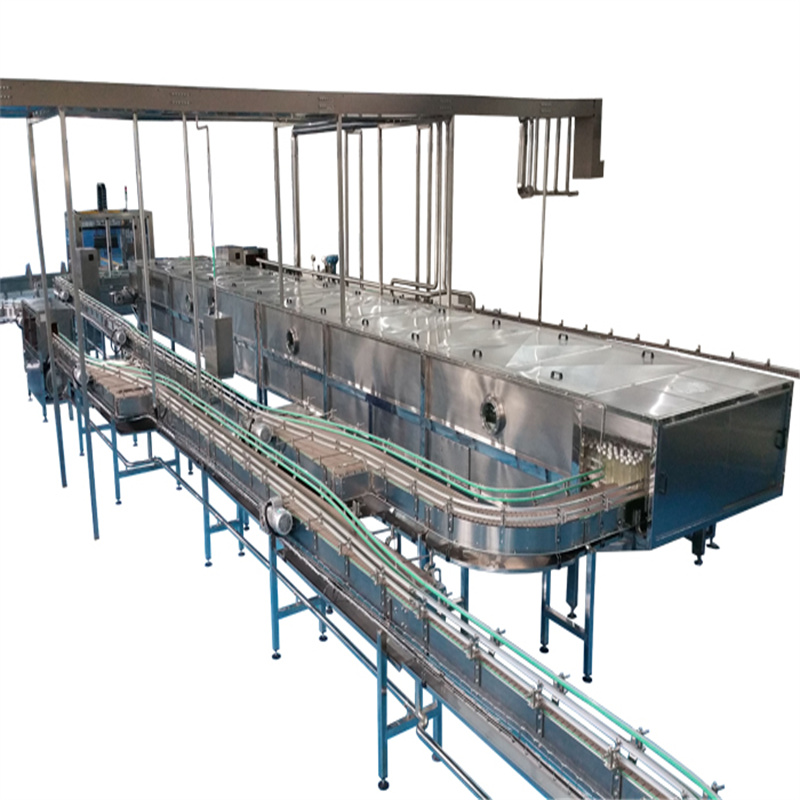

Spray Cooling Tunnel Pasteurizer for Bottling Fruit Juice Diary Beverages

Description

The spray type pasteurization and cooling tunnel uses circulating warm water spray for preheating, circulating hot water spray for pasteurization, warm water pre-cooling, cold water cooling four-stage treatment or multi-stage treatment, pasteurizing and cooling beverage to ambient temperature and sent to the next station for further processing. The whole process is fully automatic, pasteurization and cooling time can be designed according to user needs frequency conversion speed.

Product Attributes

| Model NO. |

| KYSJ00 |

| Warranty |

| 12 Months |

| Chain-to-Ground Height |

| 1050±50mm |

| Capacity |

| Customized |

| Rack Height |

| According to Container′s Height |

| Rack Length |

| 1600mm (According to Customers Process Requirement |

| Rack Width |

| 2000mm |

| Compressed Air Source |

| 0.8MPa |

| Gas Consumption |

| 0.05m3/Min |

Parameters

| Item | Parameter |

| Capacity |

|

| Height from spray sterilizer chain to the ground | H=1050±50mm |

| Height of the frame | according to the height of the bottle |

| Length of rack | effective length +1600mm (according to customer's process requirements) |

| Frame width | 2000mm |

| Compressed air source | 0.8MPa |

| Air source consumption | 0.05m3/min |

Application

The SUNRISE spray Cooling Tunnel is applied to pasteurizing and cooling of various bottled and canned beverages, dairy products canned fruits and vegetables juice/sauce, etc. It can also be used for warming of carbonated drinks beverages.

Spray cooling tunnel host module--The overall size of the machine is determined according to the product output and customer process requirements, and the height is determined according to the product height. The seal design of the inlet and outlet is carried out. The height of the chain network can be adjusted from 1000 to 1100mm, and the running speed of the network belt can be adjusted from 0 to 1000mm/min. The main frame is made of high-quality stainless steel. Upper sprinkler of the spray sterilizer adopts industrial grade stainless steel seamless tube, in case of high pressure burst. It is equipped with cleaning manhole and overflow port to facilitate personnel to enter the equipment to clean and remove equipment residual liquid. Equipped with window, you can observe the operation of production.

Solution

PET bottle fruit juice filling production line.