OEM/ODM Manufacturer Cap,Fill Level& Code Inspection System - Vacuum and Pressure Inspection Machine for Tin Cans Beverage – Sunrise

OEM/ODM Manufacturer Cap,Fill Level& Code Inspection System - Vacuum and Pressure Inspection Machine for Tin Cans Beverage – Sunrise Detail:

Product Attributes

| Model NO.:TJYDJ15 |

| Type: Vacuum and pressure inspector |

| Brand: T-Line |

| Customized: Yes |

| Transport Package: Wooden Case |

| Application: Three or four screw cap glass bottles of food, medicine, health products, drinks, three-pieces can drinks, eight treasure porridge, condiments, canned |

Product Label

Vacuum inspection machine,pressure inspection machine,vacuum and pressure inspector,detection machine,vacuum detector,online testing system,cans vacuum inspection system,detection machine,detecting system,can vacuum and pressure tester,detection,inspection machine,checker, glass bottle production line,pop can production line.

Product Details

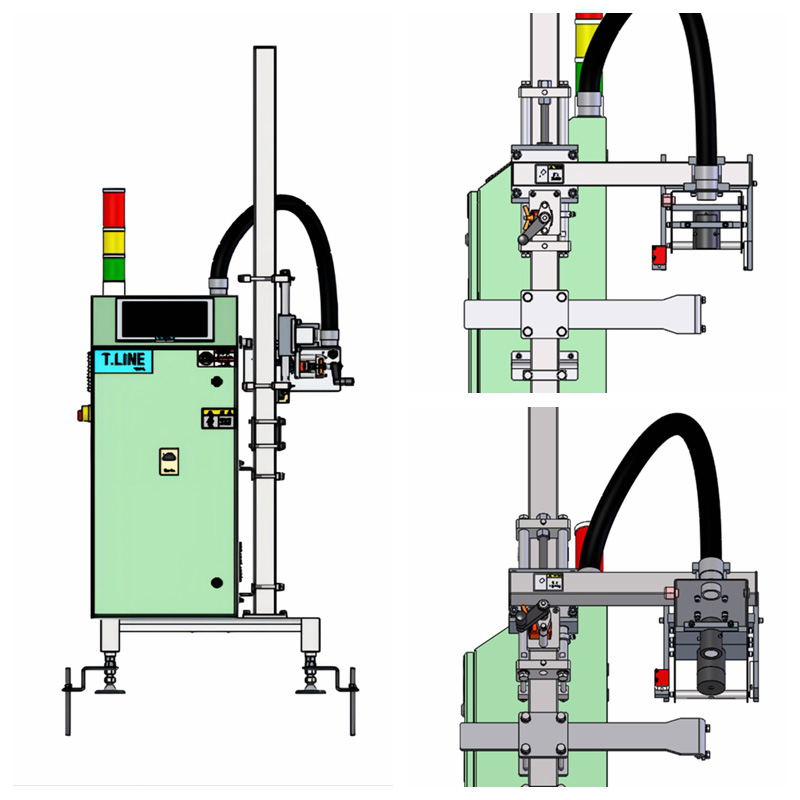

Equipment introduction

This machine is a fully automatic multi-function inspection system equipment, the inspection speed is up to 1500 cans/min, it adopts non-contact online inspection method to detect quality defects caused by low pressure or insufficient vacuum, and its inspection principle is based on horizontal acoustic technology and scanning technology.

Equipment principle

Using acoustic technology to detect iron-capped containers.When the container passes the vacuum detection probe,the probe emits high-energy electromagnetic waves to impact the lid of the container non-contact, the lid impact sound, sound with vacuum container has the certain proportion relationship. The unique sound analysis method can achieve high accuracy and continuity.

Scanning technology is used to detect the deformation of the lid of the iron-covered container, and the quality of the container is judged by the deformation of the lid.When the container passes through the curved scanning probe, the probe continuously detects the distance between the probe and the lid, and outputs a proportional analog voltage. The analog voltage passes through the data processing system to produce a value of the lid shape quality. If detected unqualified products, immediate feedback and elimination.

Implement the detection function

vacuum online detection, pressure detection, no lid, deflated can detection, double lid, pour can detection, swell can detection, reverse can detection, etc.

Suitable for the following container and closure types:

Containers: cans, glass bottles, etc.

Sealing type: can iron bottom, glass bottle crown cap, glass bottle triple screw cap, etc.

Technical parameter

| Dimension(L*W*H) | 624*655*1963mm |

| Suitable conveying height | 600-1400mm |

| Material | SUS304 waterproof level IP65 |

| Rejection rate of unqualified products | ≥99.9% |

| Communication | AC220V/ Single phase |

| Power | 0.5kw |

| Capacity | 1500 cans/min or conveyor belt ≤ 120 m/min |

| Air consumption | ≈0.01 L/time |

| External air source | >0.5Mpa |

| External air interface | Outside diameterΦ10 Air pipe |

| External air source flow | >500 L/min |

Structure characteristic

Non-contact detection

Chinese and English bilingual menu

Color man-machine interface operation

Up to IP65 rated enclosure

Reliable high-speed hitting

Continuous hit alarm

Ten product types are stored

10 groups of culling data saved

digital signal processing

Pendant Probe Assembly

Precise hit timing encoder

Built-in microphone for online monitoring and recording

Alarm information

Network remote control (optional)

Product detail pictures:

Related Product Guide:

To create far more benefit for customers is our company philosophy; customer growing is our working chase for OEM/ODM Manufacturer Cap,Fill Level& Code Inspection System - Vacuum and Pressure Inspection Machine for Tin Cans Beverage – Sunrise , The product will supply to all over the world, such as: Puerto Rico, Salt Lake City, Guinea, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We now have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.