Factory source Packaging Box - Aseptic Filling System for Milk Beverages in PET Bottle – Sunrise

Factory source Packaging Box - Aseptic Filling System for Milk Beverages in PET Bottle – Sunrise Detail:

Description

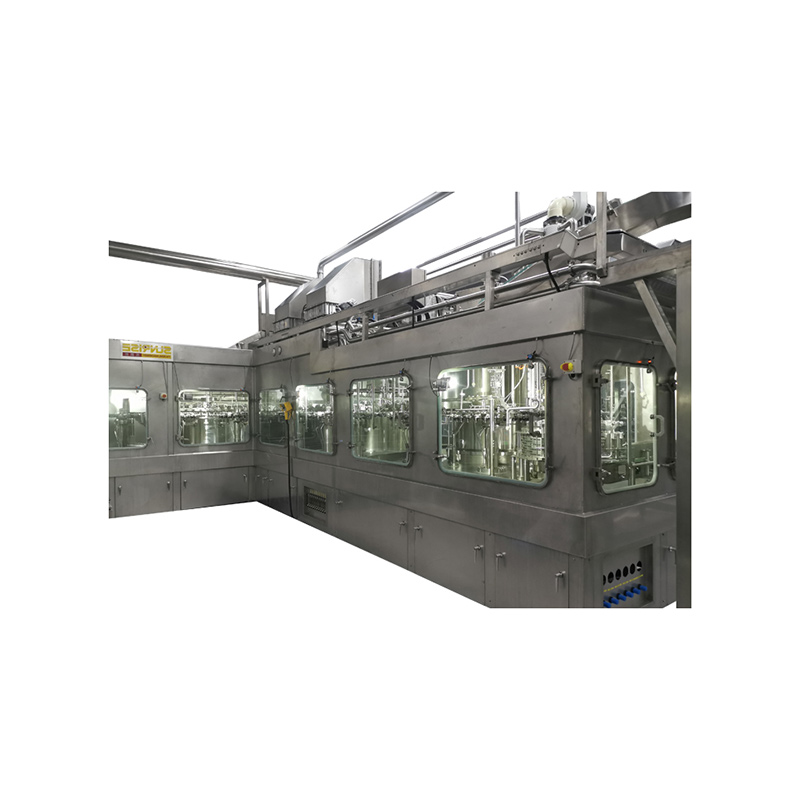

Aseptic cold filling system: Aseptic products are filled and capped in aseptic containers under aseptic environment at room temperature. SUNRISE PET bottle aseptic filling system is a collection of microbial detection and control technology, aseptic isolation technology, computer detection and control technology, cleaning and sterilization system as one of the comprehensive technology. With a wide range of beverage product adaptability, and can maximize the nutrition, color and taste of products, products without adding preservatives.

Product Attributes

| Model NO. |

| 1300908A |

| Warranty |

| 12 Months |

| Automatic Grade |

| Fully Automatic |

| Material Type |

| Mainly suitable for PET bottle tea, fruit juice, vegetable protein drinks, coffee, liquid milk and other products. |

| Capacity range |

| 15,000 bottles/hour – 36,000 bottles/hour |

| Applicable bottle type |

| 250ml-1500ml, diameter φ50 ~ 105mm; Height 140 ~ 320mm |

| Asepsis cycle |

| Neutral products ≥72 hours, acidic products ≥144 hours |

| Product filling temperature |

| Room temperature |

Advantages

⚡ 1. Asepsis cycle:Neutral products ≥72 hours, acidic products ≥144 hours

⚡ 2. Apply to both carbonated drinks and non-carbonated drinks

⚡ 3. 28 and 38 bottle mouth can be used by one machine.

⚡ 4. Fruit pulps cans be added.

Parameters

| Model | 1300908A |

| Capacity | 15000BPH(based on 500ml) |

| Module | Sterilization 80;rinsing 55;filling 35;capping 10 |

| Dimensions | L-W-H 11650*9250*4500mm |

| Weight | 26500kg |

| Applicable cap | Plastic pilferproof cap φ26~45mm |

|

Applicable bottle |

Φ: 50~105mm;height: 140~320mm;volume: 250~1500ml |

| Filling temperature | ≤15-25℃,Special products excepted |

| Applicable beverage | tea、juice、water、milk drinks、yogurt, etc.(neutral、acid products) |

| Sterilization ability | ≥6D |

| Residual disinfectant in the bottle | ≤0.5mg/L |

| Sterile cycle | 72H(It depends on the product.) |

| Filling accuracy | ±1.5% |

| Capping qualification rate | ≥99.99% |

| Power | 21.6kw |

Application

Mainly suitable for PET bottle tea, fruit juice, vegetable protein drinks, coffee, liquid milk and other products.

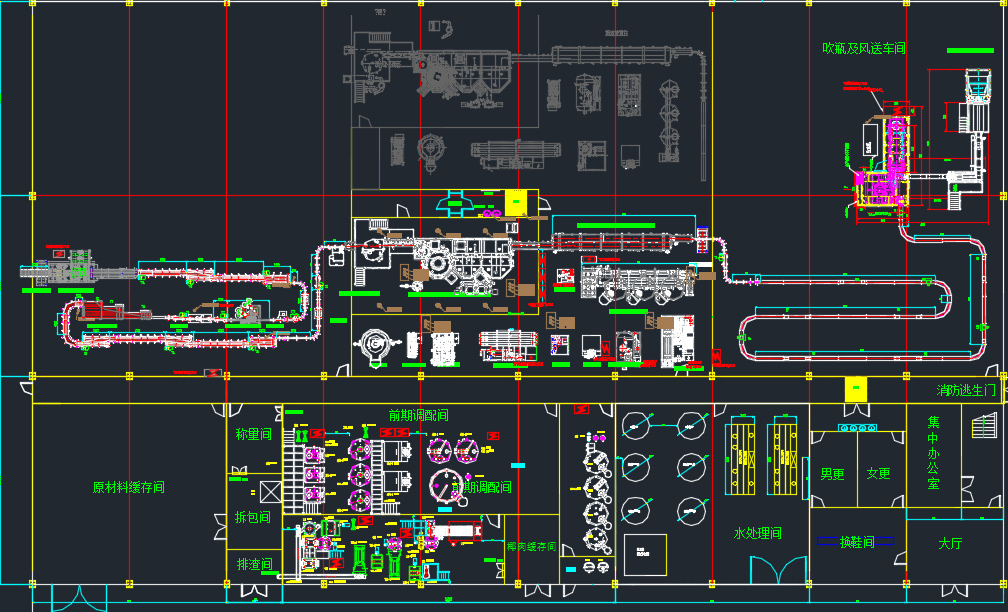

Aseptic cold filling production line includes water treatment system, pre-treatment system, bottle blowing machine, 5-in-1 aseptic cold filling machine, labeling machine, carton packing machine, robot palletizing machine and some necessary inspection equipment. SUNRISE provides one-stop turnkey project to provide customers with satisfactory service.

Aseptic filling systems for milk beverages in PET bottle

Solution

Aseptic cold filling machine in PET bottle coconut milk filling production line.

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: How long the warranty will be?

A: We provide 12 months for the main parts of the machine and lifelong service for all the machineries.

Q: How to find sunrise machine?

A: Search Alibaba, Google, YouTube and find suppliers and manufacture and not traders. Visit exhibition in different countries. Send SUNRISE Machine an request and tell your basic inquiry. SUNRISE Machine sales manager will reply you in short time and add instant chatting tool.

Q: You are welcome to our factory at any time.

A: If we can fulfill your request and you interested in our products, you may pay a visit to SUNRISE factory site. The meaning of visiting supplier, because seeing is believing, SUNRISE with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

Q: How to guarantee your funds to be safe and delivery to be on time?

A: Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy. By letter of credit, you can lock the delivery time easily. After the factory visit, You can ensure the facticity of our bank account.

Q: See SUNRISE machine how to ensure the quality!

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers’ factory.

Q: The after-sale service of SUNRISE machine!

A: After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment. According to the customer’s request, we can arrange our engineers to customers’ factory to do the installation and training. Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers’ project.

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to Always fulfill our buyer requirements. We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Factory source Packaging Box - Aseptic Filling System for Milk Beverages in PET Bottle – Sunrise , The product will supply to all over the world, such as: Roman, Turkey, United Kingdom, You can always find the products you need in our company! Welcome to inquire us about our product and anything we know and we can help in auto spare parts. We are looking forward to work with you for a win-win situation.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!