Factory best selling Pressure Leak Detection – Full Automatic Glass Bottle Filling Production Line Machine – Sunrise

Factory best selling Pressure Leak Detection – Full Automatic Glass Bottle Filling Production Line Machine – Sunrise Detail:

Description

Complete bottling lines and individual bottling equipment like fillers and bottle washing machines for glass bottles. Many of these lines are used for beverage but they are suitable for water applications as well. We provide wide variety of complete PET filling lines and cans filling lines in addition to these glass lines and related equipment.

Product Attributes

| Model NO. |

| KYGHF08A |

| Warranty |

| 12 Months |

| Packaging Material |

| Glass Bottle |

| Capacity |

| 8000bph |

| Total Power |

| 6kw |

| Outline Dimension |

| 5800mm×3000mm×2780mm |

| Weight |

| 9000kg |

| Height of The Bottle Feeding Distance Fr |

| 1050±50mm |

Advantages

● Up to 12000BPH

● Has CIP system

● Adopt micro negative pressure filling principle

● Can add one more set of washing part to warm glass bottles or sterilize the glass bottles

Parameters

| Item | Parameter |

| Applicable bottle type | glass bottle |

| Bottle diameter | φ50~106mm |

| Bottle height | 335±10mm |

| Filling type | High-level tank flow automatically, the negative pressure hot filling |

| Filling accuracy | ±5mm(liquid surface positioning) |

| Total water consumption | 0.3Mpa,2m³/h |

| Total air consumption | 0.8Mpa,0.1m³/min |

Application

Suitable for filling fruit juice, soy milk, walnut drinks, etc into glass bottles.

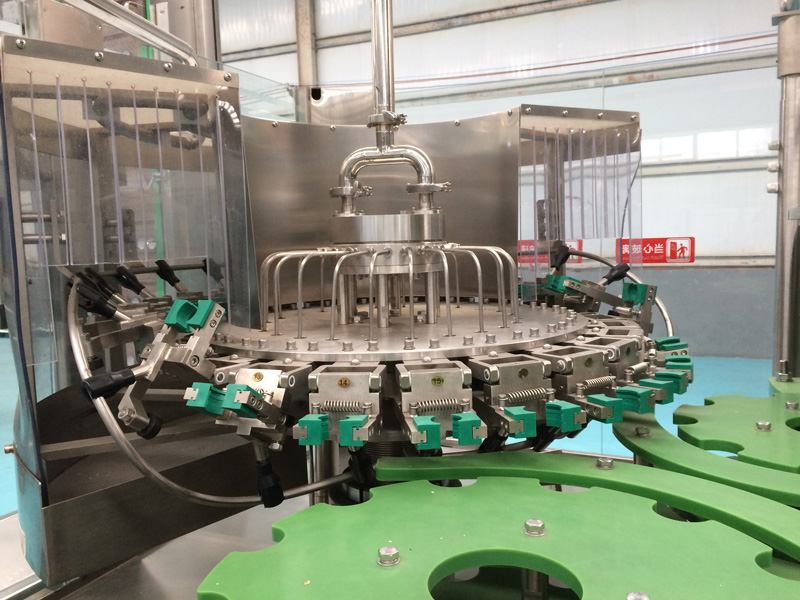

Washing part: rinsing bottle pump can be high temperature resistance; Spray nozzles adopt solid conical nozzle, the nozzle angle is 15°,rinsing with dead angle; rinsing bottle time>2s, draining bottles time>1.5s, that can be ensured rinse thoroughly and also can be up to standard residue quantity in bottle.

Filling part: CIP cleaning; equipped with automatic switching valve、temperature sensor. When the materials temperature is low, the machine will not fill and switch to return tank.

Capping part and CIP false cup: Using the combination of pre-screwing cap and screwing cap, greatly improve the capping pass rate. Synchronous belt prevents bottle from slipping.

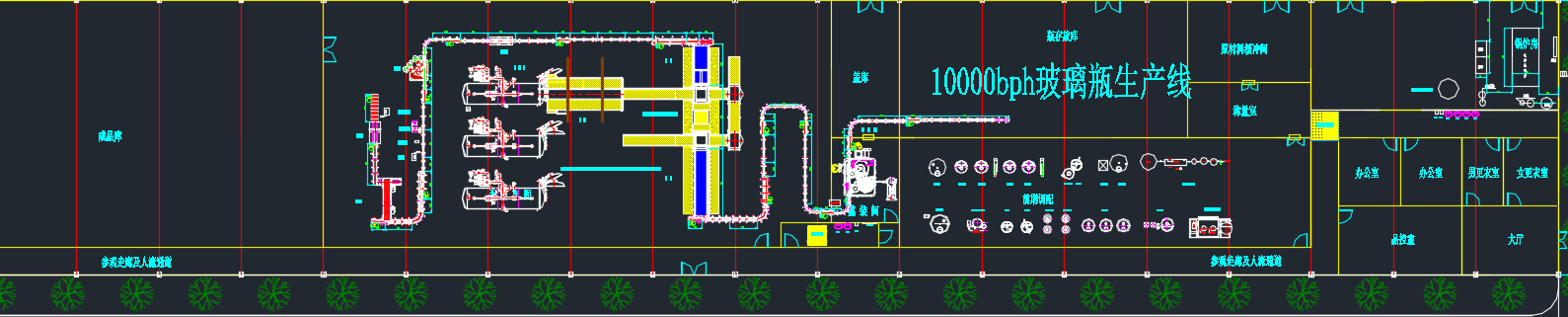

Glass bottle filling machine in walnut drinks filling production line

Solution

Glass bottle filling machine in 10000BPH glass bottle walnut drinks filling production line.

Product detail pictures:

Related Product Guide:

As for competitive charges, we believe that you will be searching far and wide for anything that can beat us. We will state with absolute certainty that for such excellent at such charges we have been the lowest around for Factory best selling Pressure Leak Detection – Full Automatic Glass Bottle Filling Production Line Machine – Sunrise , The product will supply to all over the world, such as: Jamaica, Madras, Las Vegas, We have been sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy you with our high-quality products and solutions and perfect service . We also warmly welcome customers to visit our company and purchase our products.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.