China Factory for Packaging Sealing Machine - CSD Soft Drinks Beverage PET Can Filling Line Packing Machine – Sunrise

China Factory for Packaging Sealing Machine - CSD Soft Drinks Beverage PET Can Filling Line Packing Machine – Sunrise Detail:

Description

It can fill in PET can , aluminum can, slim aluminum can ,metal cans, from the can volume 100ml -1000ml .

The Filler is driven by the Seamer for synchronized operation. The new designed filling machine integrates the multiple CIP functions, lube-free filling lifter and motorized working height adjustment, etc.

Advantages

⚡ 1. Can filling soft drinks, cola, sparkling wine.

⚡ 2. We provide one-stop service.

⚡ 3. Adopt micro negative pressure filling principle.

Parameters

| Main parameters | |

| Description | Mono-bloc washing-balanced pressure filling – capping unit |

| Capacity | 6000-24000BPH |

| Material | Body-SUS304 |

| Rinsing pressure | 0.25-0.3Mpa |

| Filling temp | ≤4℃ |

| Filling precision | ≤+1mm |

| Filling pressure | 0.25-0.4Mpa |

| Compressed air pressure | 0.4-0.6Mpa |

Application

It is mainly used in filling and capping carbonated beverages like soft drinks, cola, sparkling wine, etc.

Aluminum can filling and sealing machine base on the advanced assembling machine model from abroad, the design of GF series filing machine assembling machine incorporated the real demands from the local market, which propositions the best fit to local beverage industry, especially for cans filling and sealing.

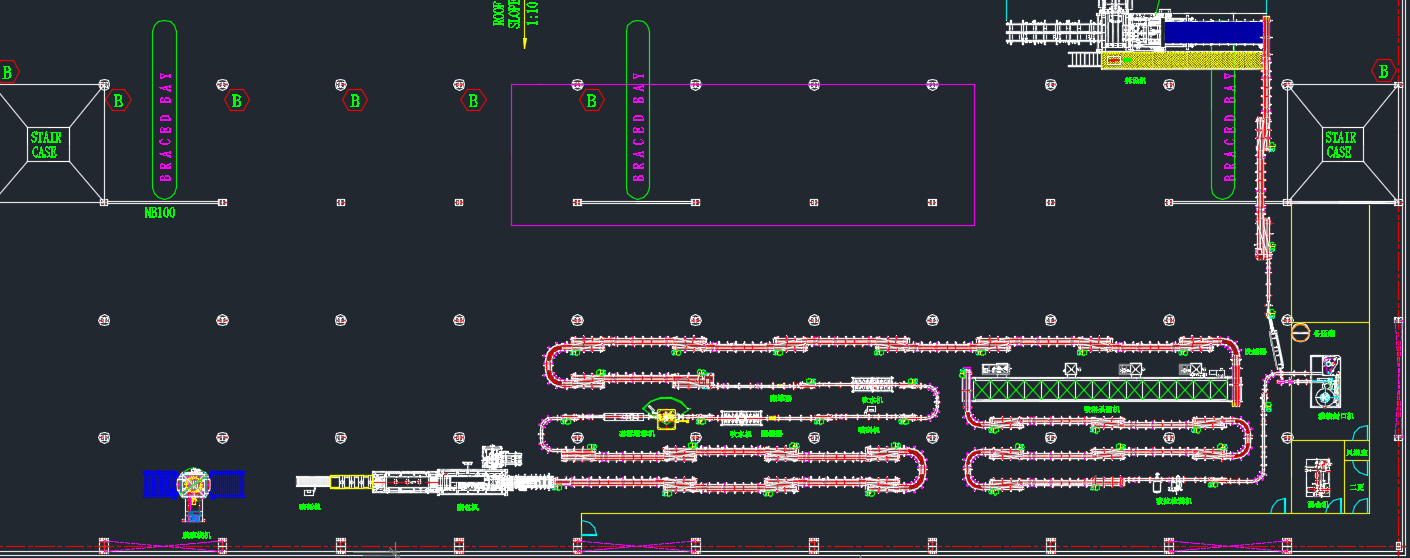

The carbonated cans production line includes water treatment system, pre-treatment system, empty cans depalletizer, empty cans waser, filling and capping machine, spray warmer cooling tunnel, carton packing machine and palletizing machine. SUNRISE can provide one-stop service, has a strong resource integration ability, to provide you with a comprehensive service.

Solution

Carbonated drinks production line in cans

FAQ

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: How long the warranty will be?

A: We provide 12 months for the main parts of the machine and lifelong service for all the machineries.

Q: How to find sunrise machine?

A: Search Alibaba, Google, YouTube and find suppliers and manufacture and not traders. Visit exhibition in different countries. Send SUNRISE Machine an request and tell your basic inquiry. SUNRISE Machine sales manager will reply you in short time and add instant chatting tool.

Q: You are welcome to our factory at any time.

A: If we can fulfill your request and you interested in our products, you may pay a visit to SUNRISE factory site. The meaning of visiting supplier, because seeing is believing, SUNRISE with own manufacture and developed& research team, we can send you engineers and make sure your after sales service.

Q: How to guarantee your funds to be safe and delivery to be on time?

A: Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy. By letter of credit, you can lock the delivery time easily. After the factory visit, You can ensure the facticity of our bank account.

Q: See SUNRISE machine how to ensure the quality!

A: In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years. Each component before assembly needs strictly control by inspecting personnel. Each assembly is in charged by a master who has working experience for more than 5 years. After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers’ factory.

Q: The after-sale service of SUNRISE machine!

A: After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools. After the commissioning, we will package the equipment by standard export package for shipment. According to the customer’s request, we can arrange our engineers to customers’ factory to do the installation and training. Engineers, sales managers and after-sales service manager will form an after-sales team, online and off line, to follow the customers’ project.

Product detail pictures:

Related Product Guide:

Sincerity, Innovation, Rigorousness, and Efficiency is the persistent conception of our firm for the long-term to create jointly with consumers for mutual reciprocity and mutual reward for China Factory for Packaging Sealing Machine - CSD Soft Drinks Beverage PET Can Filling Line Packing Machine – Sunrise , The product will supply to all over the world, such as: Bolivia, Greenland, Holland, Our solutions have national accreditation standards for experienced, premium quality goods, affordable value, was welcomed by people around the globe. Our products will continue to increase in the order and look forward to cooperation with you, Truly must any of people goods be of interest to you, make sure you letus know. We're likely to be delighted to give you a quotation up on receipt of one's in depth specs.

This company has the idea of better quality, lower processing costs, prices are more reasonable, so they have competitive product quality and price, that's the main reason we chose to cooperate.