Cheap PriceList for Visual Inspection Camera System - Labeling Inspection Machine for Pet Bottles Beverage Plant – Sunrise

Cheap PriceList for Visual Inspection Camera System - Labeling Inspection Machine for Pet Bottles Beverage Plant – Sunrise Detail:

Product Attributes

| Model NO.: TJBJGM |

| Type: Labeling inspector |

| Brand: T-Line |

| Customized: Yes |

| Transport Package: Wooden Case |

| Application: PET bottle juice drinks,water,tea drinks,energy drinks,milk drinks etc. |

Product Label

Label inspector,labeling inspection system,labeling detection machine,label detecting machine, label checker,vision inspection system,label tester,labeling testing machine,label checking machine,PET bottle production line,online testing system.

Product Details

Introduction

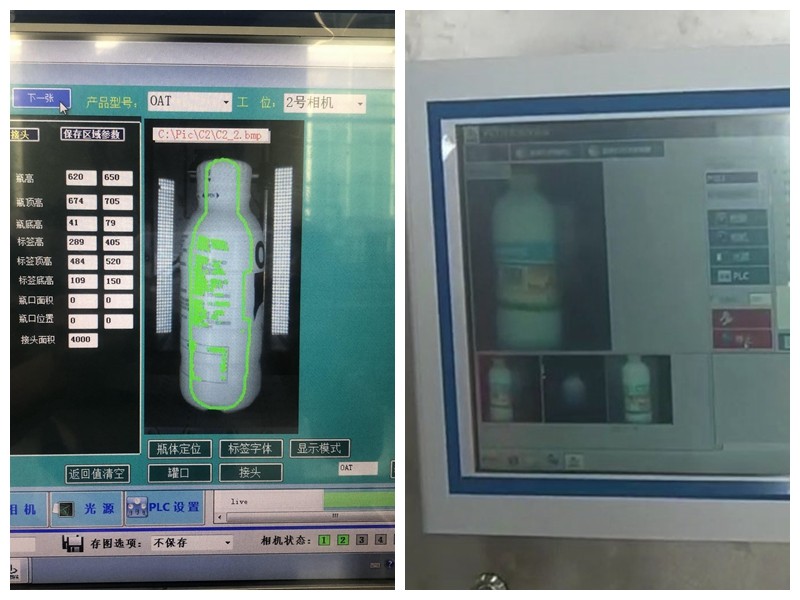

The equipment is made up of detection unit, HMI, control unit and rejector, suitable for label detection of high speed PET bottled production line.

Detection function: no label detection,wrinkled label detection, crack label detection, joint label detection, misalignment label detection, high and low label detection and displacement label detection, etc.

Technical parameters

| Dimension | (L*W*H)700*650*1928mm |

| Power | 0.5kw |

| Voltage | AC220V/single phase |

| Capacity | 1500 cans/minute |

| External air source | >0.5Mpa |

| External air source flow | >500L/min |

| External air source interface | Outside diameter φ10 air pipe |

| Air consumption of rejector | ≈0.01L/time(0.4Mpa) |

| Detection speed | Conveyor belt≤120m/min |

| Temperature | 0℃~45℃ |

| Humidity | 10%~80% |

| Altitude | <3000m |

The equipment adopts a professional image processing system, which can realize 360-degree all-round detection. The simple design of the bottle changing lifting mechanism can quickly adapt to various bottle types through simple manual adjustment. The compact inspection cabinet minimizes the equipment footprint. The detection operation status and fault conditions are displayed on the man-machine interface with pictures and texts. The detection unit can also be configured according to customer requirements.

Technical parameter

| Dimension | 900*800*2600mm |

| Materials | SUS304 |

| Total power | 0.7KW |

| External power supply | AC220V/single phase |

| Power frequency | 50/60HZ |

| Speed | 1500 ph/min |

| External air source | 0.5Mpa |

| Air consumption | 0.01L/time |

Equipment features and layout

Light source: LED surface light source, with a life span of 30,000 hours, using the backlight illumination method, the edge contour of the object to be measured can be clearly outlined; in the image, the marked part is black, and the non-marked part is white, forming a “Black and white” images that are convenient for system analysis and processing.

Lens: Using manual aperture fixed focus lens, by adjusting the “focus adjustment ring” to make the image imaged on the CCD target surface the clearest, and by adjusting the “aperture adjustment ring”, the brightness of the image is optimal.

Camera: The area array CCD analog camera is used, the resolution of the camera is 640*480 pixels, and the image acquisition speed can reach 80 frames/second.

Layout diagram: After the labeling machine, it is required to be on a single-segment chain path of more than 1500mm, the relative clearance of the bottle during the running process is more than 2cm, the relative jitters of the chain at the installation position is relatively small, and the guardrail is smooth

Product detail pictures:

Related Product Guide:

We keep on with the basic principle of quality to start with, support very first, continuous improvement and innovation to meet the customers for your management and zero defect, zero complaints as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for Cheap PriceList for Visual Inspection Camera System - Labeling Inspection Machine for Pet Bottles Beverage Plant – Sunrise , The product will supply to all over the world, such as: Angola, Angola, Swaziland, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.