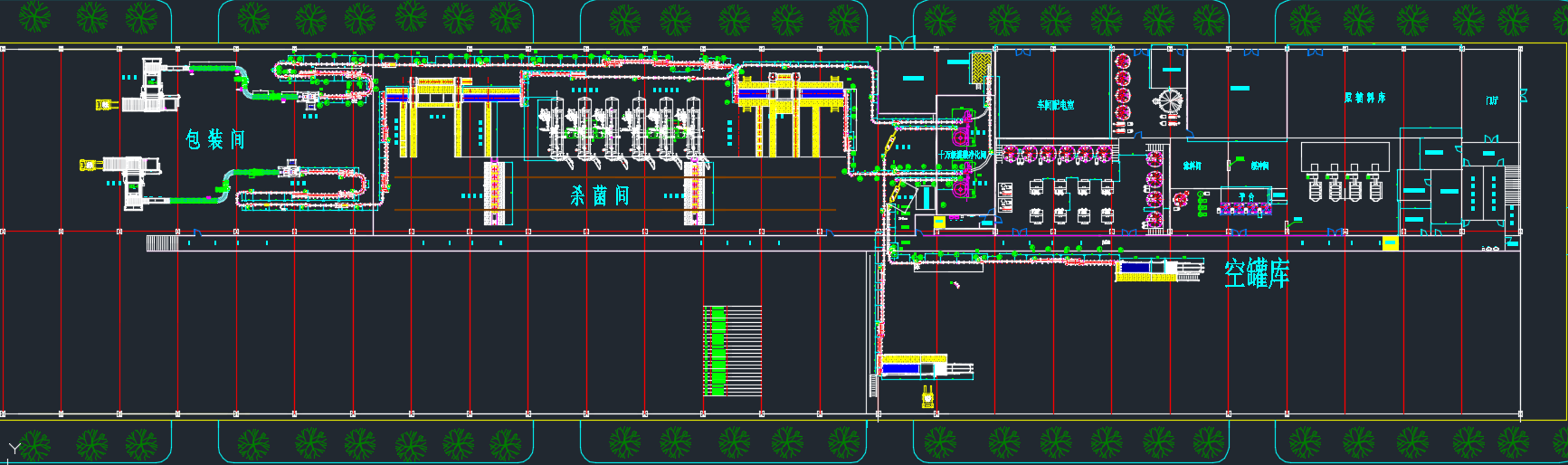

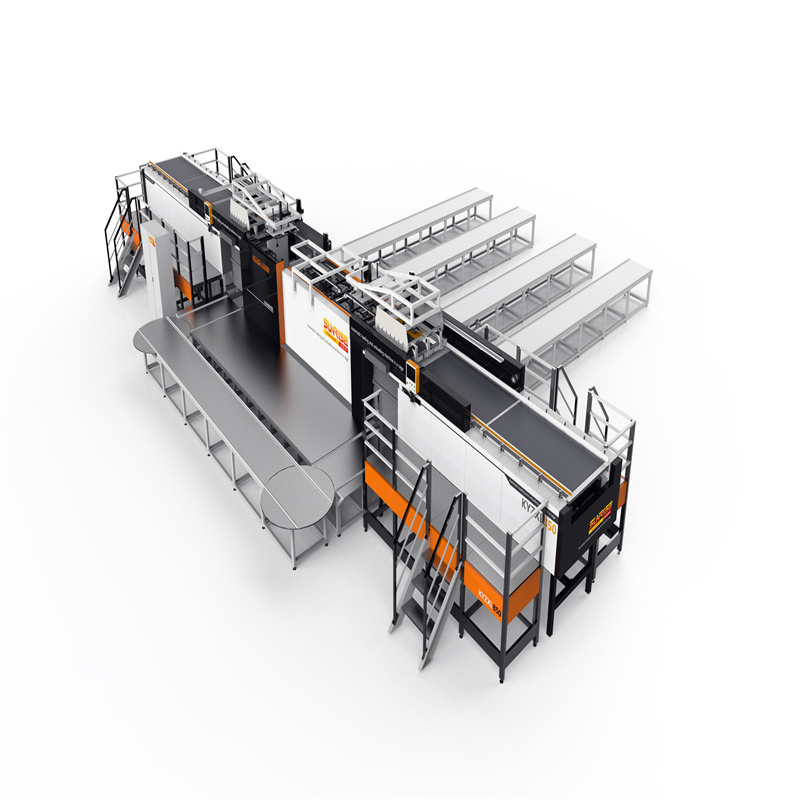

Canned Products Cage Loading and Unloading System Linked with Retort

Description

The cage loading and unloading system is mainly applied to cans. Before sterilization, the equipment is used for automatic caging, through modular mesh chain conveyor to transport cans. The cans is divided into whole columns and from the bottom up layer after layer automatically installed in the cage, through the cage conveyor system transport to the sterilization pot for sterilizing. During the whole loading cage process, the partitions are inserted automatically, rising automatically, dividing and loading cans automatically, falling automatically. When the cage is full, the cage stops filling automatically. The perfect configuration mechanism is used to replace the manual loading cans, which saves manpower and greatly improves production efficiency.

Product Attributes

| Model NO. |

| KYZXL |

| Warranty |

| 12 Months |

| Total Power |

| 6.5kw |

| Total Weight |

| 3000kg |

| Power Supply |

| 3*380V*50Hz |

| Control Power Supply |

| DC24V/AC24V |

Advantages

Can handle the need for high temperature sterilization of milk drinks, herbal tea drinks.

Parameters

| Item | Parameter |

| Capacity | 200-800cpm |

| Compressed air | 0.8Mpa |

| Air Consumption | 0.3m3/min |

| Total weight | 3000kg |

Application

Loading and unloading the cages transported to the retorts for sterilization.

Loading cage machine--Through the modular mesh belt conveyor to conveying filled can, the filled can is divided into whole layers, and then it is automatically stacked in the sterilization cage from bottom to top. During the whole cage loading process, the inserting plate is automatically put in and raised, the can is divided and filled automatically, auto down.Full cage automatic stop. With the perfect configuration mechanism to replace the manual filling mode, greatly improve the production efficiency.

Encircling structure

Encircling structure

Cage loading and unloading system used in PE bottle coconut milk filling production line.

Solution

Cage loading and unloading system in cans almond juice filling production line.